As it stands, OPPO is basically a smartphone manufacturing company even though it is planning to shift its focus to internet-based business next year. The brand’s smartphone has seen a tremendous change since the OPPO Find 7 bestrode the tech scene donning as its biggest feature a VOOC fast charge technology. Since then, several models including flagships like the OPPO Reno, Find X2 and others have been released.

OPPO recently took some media personnel on a tour of one of its nine factories in Shenzhen where it manufactures most of its models including the Reno 2, the upcoming Reno 3 5G, and the Find X2, which have proved popular in Europe and India.

The factory is adorned with reels of resistors, transistors, and capacitors fed through expensive machinery that automates the manufacture of motherboards. Robotic arms, like those you’d find on any assembly line, put newly minted phones through dual-camera, antenna, and GPS tests.

EDITOR’S PICK: First Samples from the 108MP Mi Mix Alpha is here & we are not impressed!

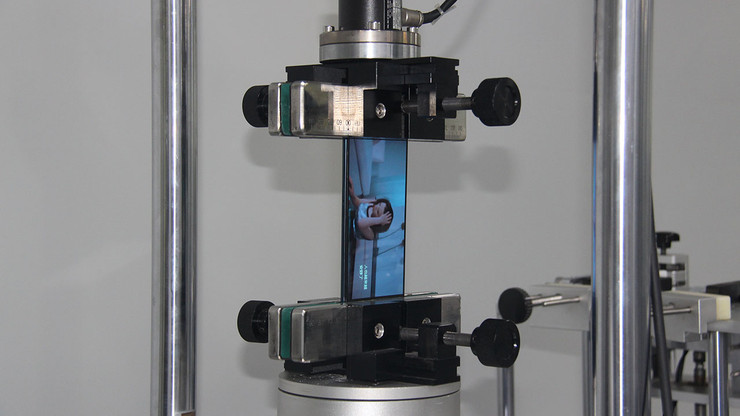

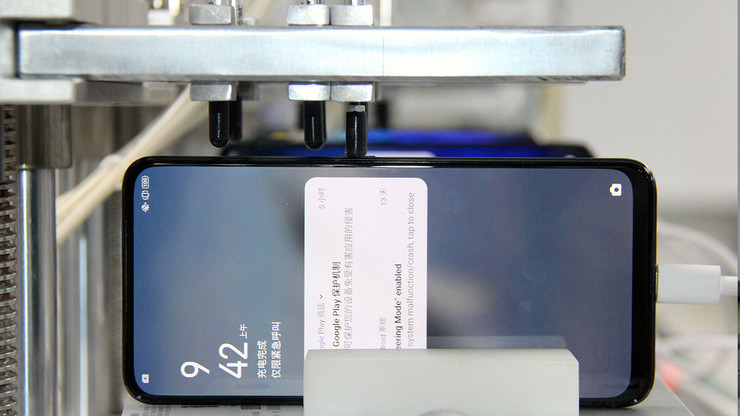

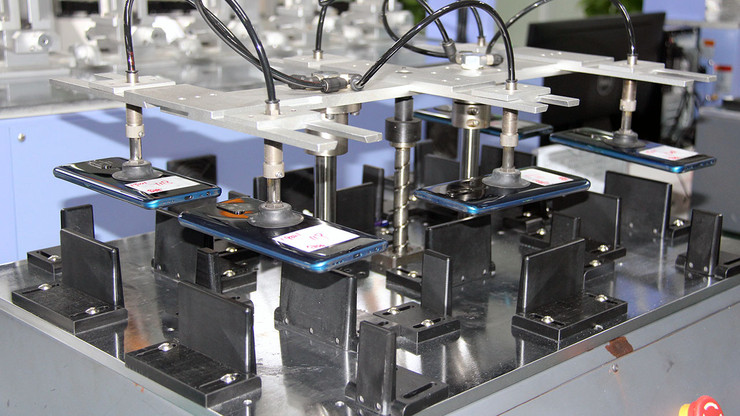

The smartphones are put into two rooms at the end of the manufacturing process, the phones. One of the rooms is made out of metal and it reflects radio waves and tests the average power of the device. The second room is completely dark and mimics the phone being used in an infinite space without any invisible interference. Before the phones are finally packaged for shipment they go through several rigorous testing such as drop tests. The charging ports, cables, power/volume buttons are also subjected to rigorous tests to ensure they’ll stand the stress of daily usage.

We recall Xiaomi also took the media on a tour of its Foxconn factory showing a similar routine. So this all seems to be a standard routine. Check out pictures from the factory.

UP NEXT: Xiaomi Mi Note 10 Pro vs OnePlus 7T vs Huawei P30 Pro: Specs Comparison

(source)