Oppo recently unveiled its Find X5 Pro flagship smartphone which came with all the cutting edge bells and whistles including the latest flagship chipsets from Qualcomm and MediaTek and even incorporates their Marisilicon X NPU chip (Snapdragon variant), however, the smartphone mostly stands out for its unique design and the never before seen ceramic back panel. So let’s take a look at why and how Oppo made this back panel possible.

With the Find X5 Pro, Oppo wanted to create a truly premium experience for its users both in the looks and feel of the device, so they decided to go with ceramic instead of glass for the back. The material has a lot of advantages compared to glass, like it is twice as tough, making it essentially drop-proof, and also has a texture that reduces fingerprints.

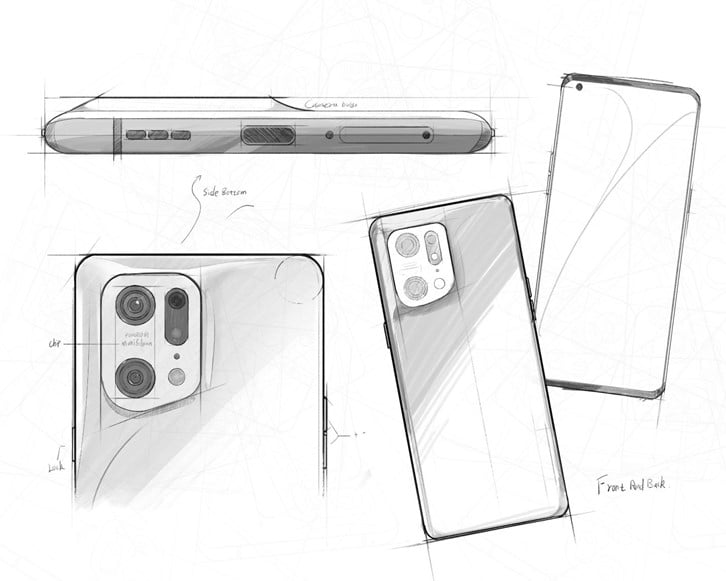

The back panel design is perfected to a tee with the use of in-house techniques of molding ceramic into an organically curved rear with a smoothness that feels like a pebble. But as we know that ceramic is one of the hardest materials out there, it proved nearly impossible to mold it using conventional methods, and therefore the engineers at Oppo invented a process from scratch to achieve the elegant design and finish of the Find X5 pro.

Oppo claims to have invested millions to develop specialized automated equipment which utilizes over 2,000 individual control points to achieve the uniquely curved ceramic rear panel of Find X5 pro and its iconic seamless camera housing.

To remove the machine marks from the back panel, engineers meticulously polish the ceramic’s edges in multiple stages, using a four-axis polishing machine and micron-level diamond powder. This process takes five whole days to produce a ceramic cover that is up to Oppo’s standards.

The Ceramic back of the Oppo Find X5 Pro has truly combined luxury with utility, which has been possible due to Oppo’s commitment to precision and perfection.

RELATED:

- OPPO to launch a clamshell phone & rollable display phone in 2022: Tipster

- Xiaomi, Oppo, Vivo in talks to make phones in India and export them globally

- Samsung Galaxy S22 Ultra vs OPPO Find X5 Pro: Specs Comparison