Sakuu, an innovative startup headquartered in Silicon Valley, has introduced a game-changing 3D printer that has the potential to transform battery production as we know it. By leveraging the printer’s capabilities, the company can create solid-state batteries that can fit into any shape or size. From smartphones to household appliances and e-bikes, these batteries can power a range of devices, making them more efficient and cost-effective.

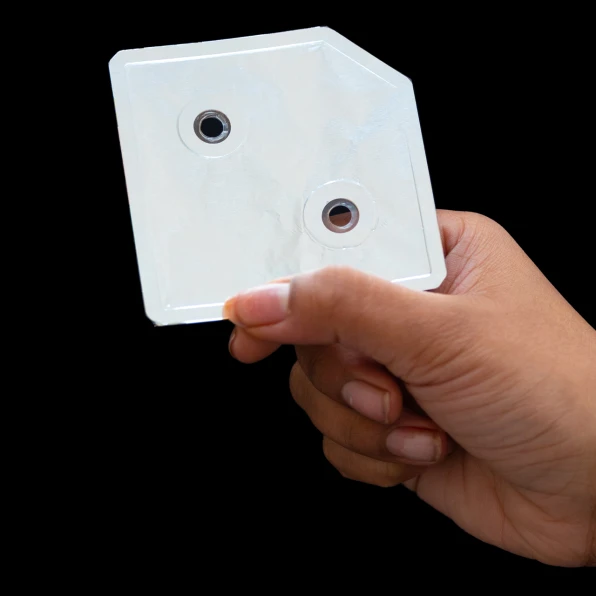

Traditionally, battery manufacturing involves laminating and stacking sheets of material, which are then rolled into cylinders or other shapes. This method, however, is not feasible for solid materials that can break easily. Sakuu’s 3D printer utilizes powder to maintain thin layers and ensure optimal performance. The technology behind the printer was developed at MIT, and it minimizes material waste, making it cost-effective.

Sakuu’s 3D printer is not only cost-effective but also space-efficient, requiring only around 400 square feet to manufacture 100 megawatt hours of batteries per year. In contrast, older machinery takes up 16,000 square feet and produces only 2.5 megawatt hours. The increased efficiency of Sakuu’s 3D printer is expected to reduce battery production costs by nearly 50%.

The company is presently working with aviation industry clients to develop airplane batteries in customized shapes to manage heat. It has also demonstrated the printer’s ability to produce functional batteries using different materials and designs, and it claims to be the first company in the world to do so. Scaling up production equipment is the next phase for the company before it licenses the technology to clients in the battery, automobile, and other sectors.

RELATED:

- Leaked iPhone 15 Pro Max 3D Models Reveal Thicker Body with Solid state Buttons

- Hydrogen Fuel Cells: Panasonic’s Answer to Sustainable Energy Need in China

- World’s Fastest Hydrogen-Powered Train Launched in China

(via)