Although it may seem strange to some, customized insoles is a big industry since many people face orthopedical problems that require custom shoes and insoles. Right now, most custom insoles are manufactured with traditional methods using CNC machining that makes production cumbersome and expensive. There are also orthotists that make custom insoles by hand but these have a long manufacturing cycle and cannot be mass-produced. Since CNC machining produces large material waste and requires expensive equipment, large floor space, and complicated operation, custom insoles are hard to become popular and widely available.

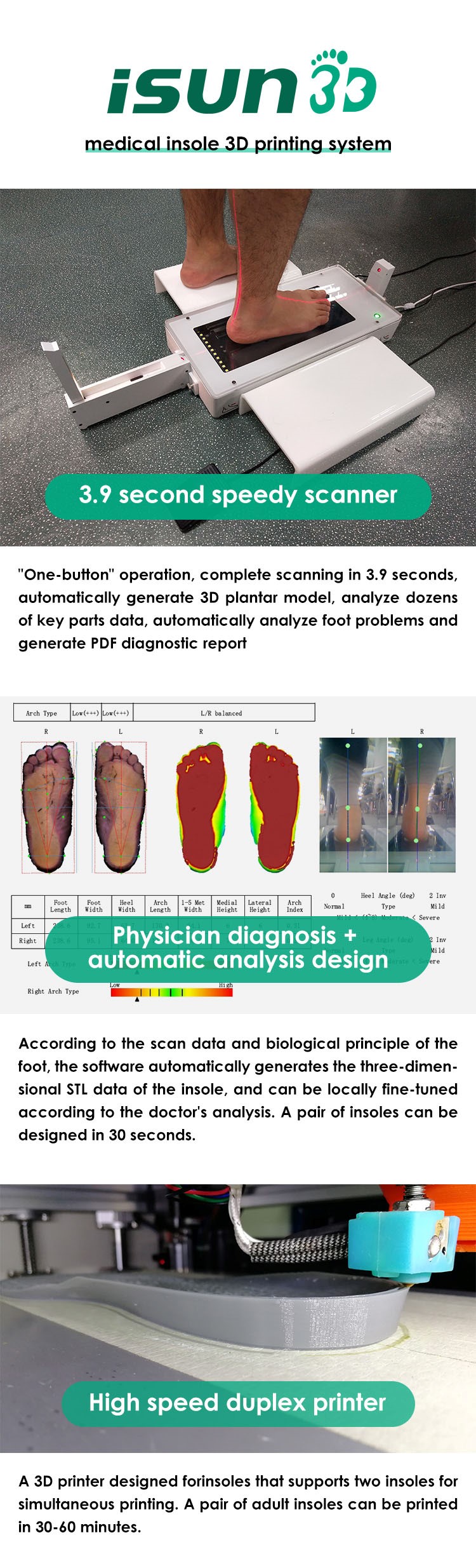

Aiming to make customized insoles widely available, eSUN has successfully developed 3D printing materials and 3D printers for customized insole mass production, creating the first medical insole 3D printing system in China.

Though the new printing system, they greatly improved the efficiency, productivity, quality and cost of similar systems. What’s more, they’ve applied for patented technology that uses 3D foot scanning to obtain user foot data and applies high soft 3D printing material and iSUN3D FLX printer to print a pair of insoles that are completely suitable for the user’s foot type.

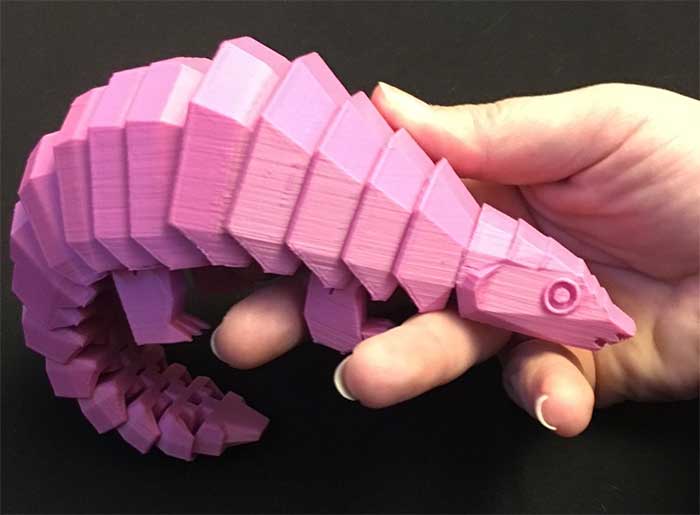

The filament used offers high flexibility and high resilience to greatly reduce permanent deformation of the material while at the same time it has moisture permeability and hydrolysis resistance. This way, the insoles can be washable and survive cold and warm conditions. As an environmentally friendly material, it prints smoothly with no odor and no need to heat the bottom plate when printing. The surface of the product is also easy to color. Using the special filament, allows the iSUN3D FLX printer to print fast, reducing the printing time from 30 hours to 30-60 minutes and the system is integrated and easy to operate.

Taking advantage of its own materials and by integrating global resources, eSun aims at putting the whole chain to practical use. They’ve already established a customized insole design and 3D printing processing center in Shenzhen and Hubei Xiaogan and they hope to build a scanning franchise network and a centralized design center by establishing a centralized print service center and forming a complete printing, design, and distribution center.

As scanning and design of current insoles are relatively mature on the market and customized insoles are no longer only hand-made or CAM manufactured, the unique creation of eSUN 3D printing insole system completely replaces the traditional customized insole manufacturing process.

Its advantages are clear since it saves manpower, focuses on environmental protection, eliminates noise and exhaust pollution, and improves the quality and performance of the insoles. In the near future, breakthroughs in 3D printing technology will significantly improve the production of traditional customized insoles.

More 3D printer and material, please visit eSun official site.