Semiconductors are tiny chips that are used in almost all electronic devices. They are essential to our modern technology, and they are used in everything from smartphones to TV remotes. During the pandemic, there was a global shortage of semiconductors. This caused production difficulties for many industries, and it led to higher prices for electronic devices. Thankfully, the chip shortage is now over. And researchers are already working on new ways to improve this technology. Most recently, researchers at King Abdullah University of Science and Technology department have developed a new microchip that uses two-dimensional (2D) materials to improve its performance. Here are the details…

2D Materials-Based Microchips Could Revolutionize Electronics

Researchers at King Abdullah University of Science and Technology (KAUST) have developed a new type of microchip that uses two-dimensional materials. 2D materials are incredibly thin, with some being only a single atom thick. This makes them very strong and lightweight, and they also have unique electrical and optical features.

However, integrating 2D materials into electronic devices has been challenging due to their fragility and the difficulty of fabricating them on a large scale. The KAUST team overcame these challenges by developing a new method for transferring 2D materials onto microchips. Researchers who made a statement on the subject describe their work as follows:

“Our motivation was to increase the technology readiness level of 2D material-based electronic devices and circuits by using conventional silicon-based CMOS microcircuits as a base and standard semiconductor fabrication techniques. The challenge, however, is that synthetic 2D materials can contain local defects such as atomic impurities that can cause small devices to fail. Also, it is very difficult to integrate the 2D material into the microchip without damaging it.”

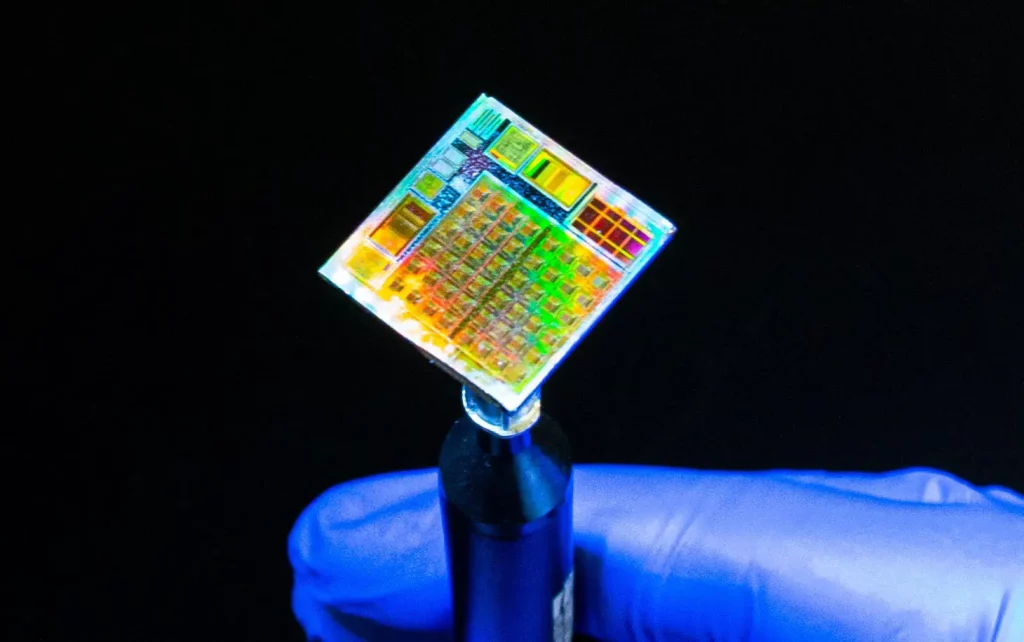

“We produced the 2D material — hexagonal boron nitride, or h-BN, on copper foil — and transferred it to the microchip using a low-temperature wet process, and we then formed electrodes over the top by conventional vacuum evaporation and photolithograpy, which are processes we have in-house. In this way we produced a 5×5 array of one-transistor/one-memristor cells connected in a crossbar matrix.”

The team is now working to improve the performance and scalability of the microchips. They are also exploring new applications for the technology. The team believes that the microchips could be used in a variety of applications, including; Wearables, flexible displays, artificial intelligence chips, medical devices, energy harvesting sensors, and Security systems. However, let’s underline that we have a long time ahead of us for these developments.

RELATED:

- Download the Best GCam APK for Poco F5

- Honor establishes chip design subsidiary following Oppo’s exit, joins Huawei, Xiaomi, and Vivo

- XMG APEX 17 & 15 gaming laptops unveiled with revamped design, 144Hz IPS displays…

- MediaTek Dimensity 9300 chip to beat Apple 17 with four powerful Cortex-X4 cores

- Samsung wants to take on Qualcomm and Google with its XR chips, says report

(via)