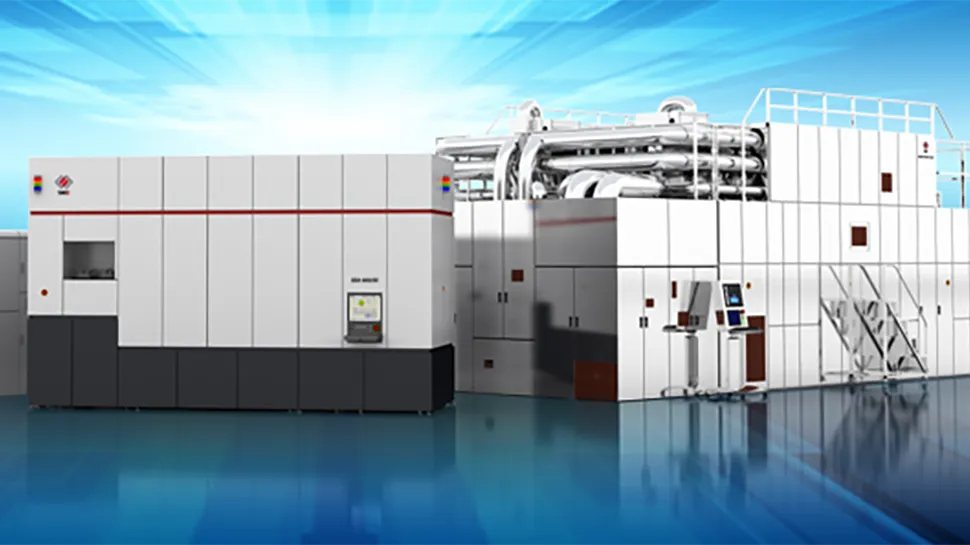

In spite of the global tech restrictions, Shanghai Micro Electronics Equipment (SMEE), China‘s leading lithography scanner producer, is gearing up to roll out its first 28nm-class fabrication process scanner by year-end. Notably, the company’s current advanced scanner only reaches the 90nm level, making the upcoming SSA/800-10W a significant milestone.

This advancement will help China become more self-reliant with its Chips

For context, lithography is a core element in chip manufacturing, and a 28nm scanner would gradually allow China to depend less on imports for chipmaking tech. With an eye on self-reliance, China is pushing hard to overcome technological boundaries, especially when global export laws make it increasingly difficult to acquire advanced chip production tools.

U.S. policies have already put a wrench in the plans of Chinese chip producers, restricting access to critical sub-14nm technologies. Additional regulations from the Netherlands, Japan, and Taiwan have compounded the issue. As a result, home-grown giants like SMIC and YMTC face roadblocks in advancing their newest manufacturing processes.

SMEE’s upcoming scanner is seen as a strategic asset that will primarily benefit either SMIC or a designated research institute. However, challenges remain. The major question isn’t just whether SMEE can create a 28nm scanner, but whether they can manufacture it at scale. Unless mass-produced, its positive impact would remain theoretical.

While the new scanner won’t bridge the advanced tech gap overnight, it will be a small yet significant step towards China’s broader ambitions in the semiconductor landscape. By carving out a domestic alternative, albeit for older but still relevant tech, China gains ground in a sector where independence is becoming ever more crucial. After all, the journey of a thousand miles begins with a single step—or in this case, a single chip.

RELATED:

- Honor Magic Vs 2 Foldable Rumoured to Launch in China This Week

- Xiaomi Mijia Smart Electric Thermos 5L is now up for pre-order in China for 279 yuan ($38)

- Download the best GCam APK for OnePlus Nord CE 3 5G

(Via)