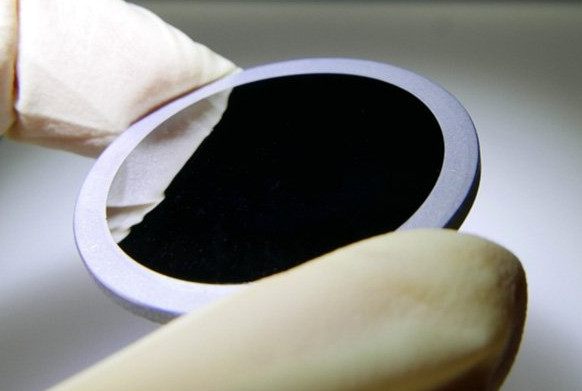

Panasonic has announced the development of a new far-infrared lens molding technology. It will be employed for the mass production of far-infrared aspherical lenses to improve camera and sensor performance. The new lenses are made of chalcogenide glass, which has “excellent far-infrared transmission characteristics.”

The new glass molding method allows Panasonic to deliver a range of lenses including diffractive lenses, which is the world’s first highly hermetic frame-integrated lens without using adhesive (via Neowin). Using the tech, the company will be able to contribute to the spread enhanced performance of far-infrared sensor modules. This will be done by achieving mass production of high-quality but still low-cost far-infrared aspherical lenses.

The new technology is ready to supply chalcogenide lenses, both aspherical and diffractive, already in a number of sizes, ranging from φ3 mm to φ40 mm. The non-usage of adhesive will also allow the production of frame-integrated lenses without the risk of gas contamination.

Further, the edge of the lens is safeguarded, improving the accuracy of installation on the lens barrel. And last but not least, the technology enables the development of highly hermetic barrel type frame-integrated lenses.

Panasonic is currently accepting prototype orders but sales of high-performance and low-cost far-infrared aspherical lenses are set to expand in the future.

RELATED:

- Panasonic Toughbook S1 Rugged tablet with Extendable battery launched for ₹98,000(~$1,294)

- LG is the world’s biggest battery maker driven by EVs, Panasonic & Samsung in tow – Report

- Google hiring ‘camera ISP’ experts for 2nd Gen Tensor chips: Report

- Xiaomi 12 Ultra could dominate DXOMark camera rankings: Exec

- RedMagic 7 series will have a model with under-display camera technology