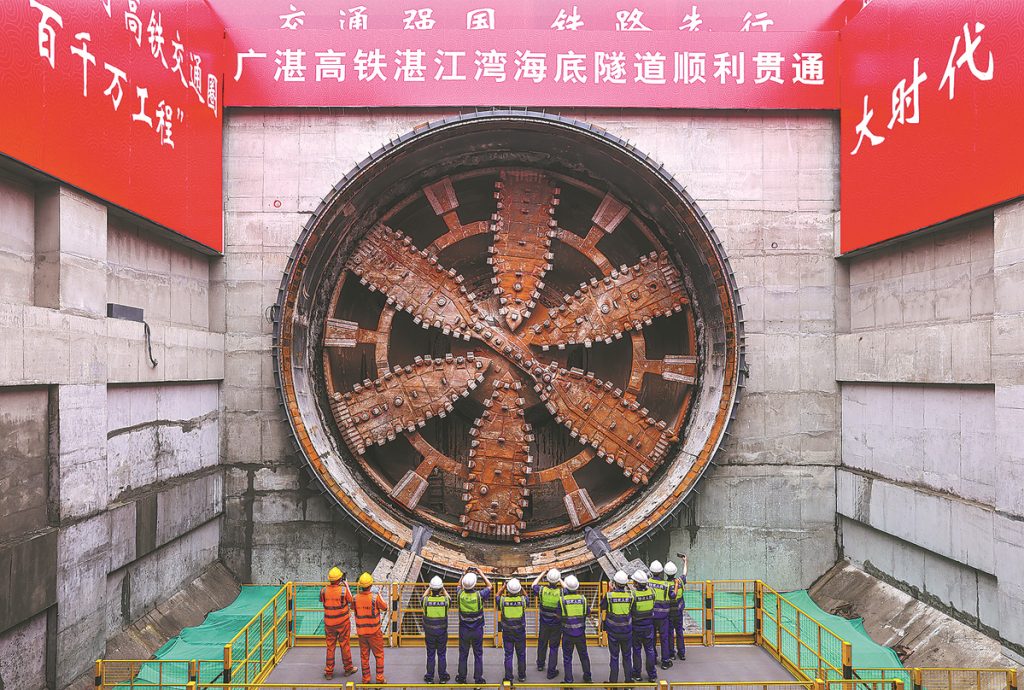

China‘s high-speed railway network keeps gaining momentum with the completion of a record-breaking undersea tunnel. The Zhanjiang Bay Undersea Tunnel, a key section of the Guangzhou-Zhanjiang High-speed Railway, marks a significant milestone in the country’s infrastructure development.

7551 meters of the tunnel was carved by a single tunnel-boring machine

Capping off 33 months of construction, the tunnel boasts an impressive length of 9,640 meters, with a staggering 7,551 meters carved by a single tunnel boring machine (TBM) named “Yongxing.” This feat makes it the longest single-headed undersea high-speed railway shield tunnel in China, showcasing the nation’s remarkable engineering expertise.

The importance of this single-headed approach lies in its efficiency and safety, particularly when dealing with complex geological conditions. Traditional methods involving TBMs excavating from both sides and meeting in the middle were deemed unsuitable for the Zhanjiang Bay project.

Imagine this behemoth burrowing as deep as 50 meters underwater, withstanding immense pressure equivalent to 5.2 kilograms on a fingernail-sized area. No wonder the team at China Railway’s 14th Bureau Group had to tailor the machine specifically for these challenging conditions!

But why a tunnel and not a bridge? The answer is multi-fold. The tunnel protects the scenic Zhanjiang Bay skyline and minimizes environmental impact on marine life. Additionally, a bridge could obstruct the passage of large vessels and be vulnerable to typhoons, a frequent occurrence in the area. A subsea tunnel bypasses these concerns, ensuring smooth and safe high-speed rail operations even during harsh weather.

This critical tunnel paves the way for the completion of the entire 401-kilometer Guangzhou-Zhanjiang High-speed Railway by the end of 2025. With a designed speed of 350 kilometers per hour, this railway line is a vital addition to China’s high-speed network. Once operational, travel time between Guangzhou and Zhanjiang will be slashed from over 2.5 hours to a mere 90 minutes. This project is sure to fuel high-quality development throughout the region.

RELATED:

- Honor Magic 6 RSR Porsche Design with 6.80-inch OLED display, SDGen3 debuts in China

- Xiaomi’s Mijia adjustable fan goes on sale in China for 329 yuan ($46)

- Xiaomi 13 Ultra Premium Camera Phone is now only $799

- Lenovo Legion Y700 2023: Save $100 on this 8-inch gaming Android tablet

- How to turn off any Samsung phone without using screen (5 methods)

(Via)