Since our first mobile phone, we have continued exploring new metal processing technologies and breaking limits. For the UMi Super, we chose lighter and solider magnalium alloy used for aircraft. After more than 100 strict processes including CNC cutting and carving, PBT nano-molding, 360-degree polishing, 3D abrasive blasting and multi-color anodizing, we scaled new heights and proudly present the unique UMi Super.

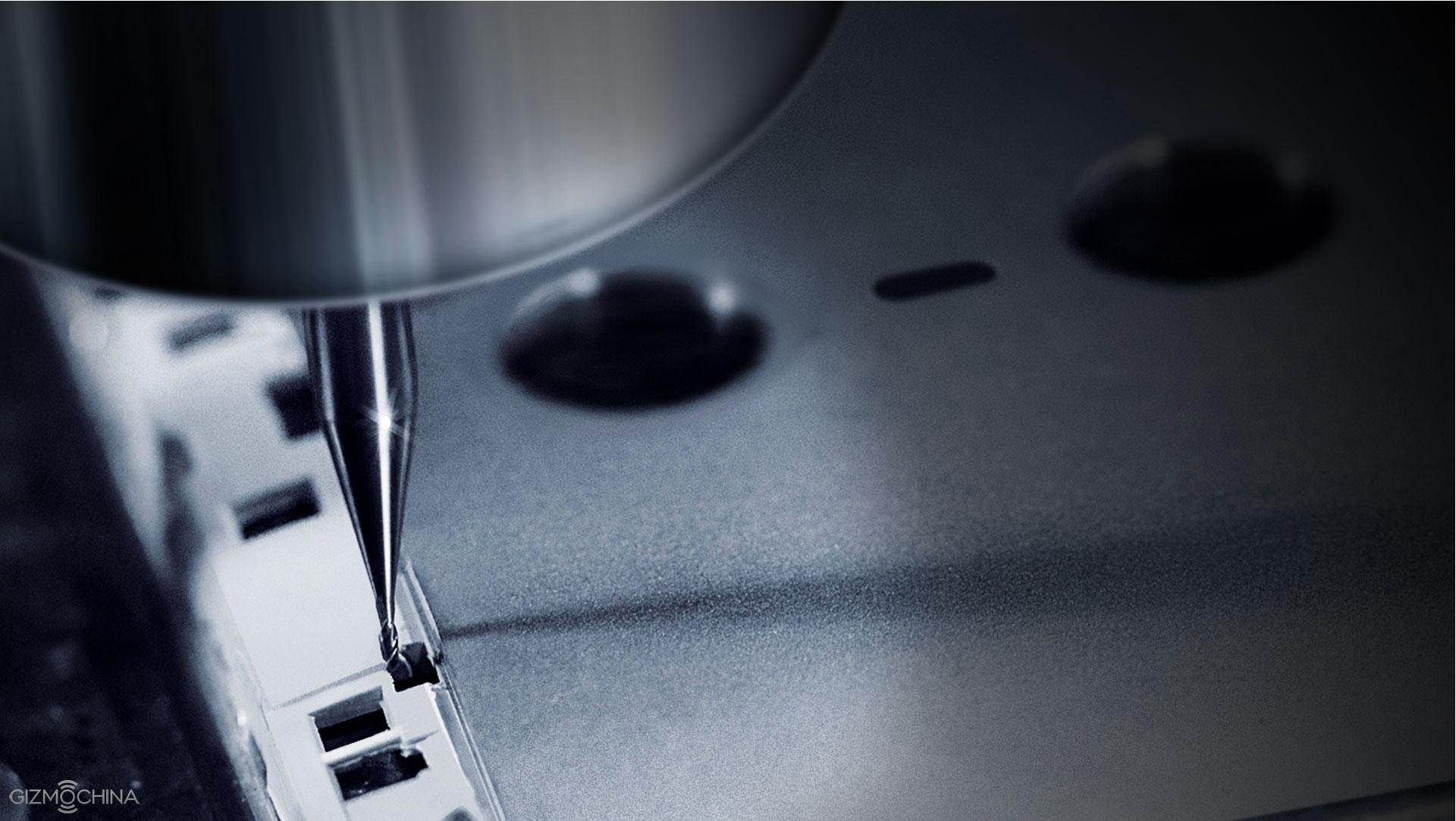

Polished Perfection

Polishing the metal body of the UMi Super takes more than you would think. It is polished after coating, and coated after polishing. This process is repeated five times, and takes more than 40 hours to complete. This is costly, but it’s the only way to ensure a perfectly uniform coloring on the metal body of the UMi Super!

Metal in the making

Despite its resilience, manufacturing the metal back cover is a delicate process. We perfected the color and touch of aluminum by sandblasting both the inner and outer sides of the back cover. This detailed process refines the edges and rims with a polished shine.

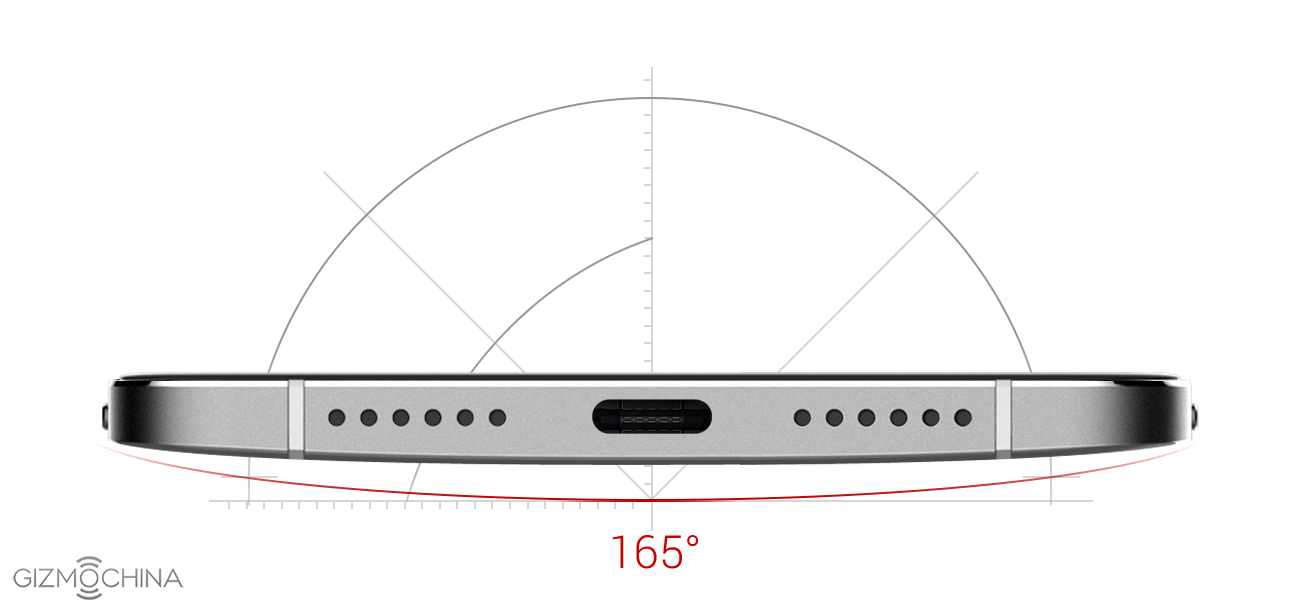

165° Palm Arc Design

Friendly curved to fit in your hand

Curved all around the edges, UMi Super has a seamless, comfortable grip that feels natural in your hand.

The best size of 4000mAh yet

UMi Super uses the latest battery technology from SONY supplier to fit an extra 26% capacity without any excess bulk. Thoughtful engineering design such as the compact circuit board and indented inner back cover maximize room for more battery.