Earlier this month, Google launched its latest flagship smartphones, the Pixel 4 and Pixel 4 XL at the “Made by Google” event which took place the U.S. Some netizens have criticised Google for the design it has implemented with its new devices, especially the thick forehead which is non-existent on almost every other smartphone in this price bracket.

While we already know, the chunky forehead has been retained to make room for the Soli Radar Chip, recently published iFixit teardown of the Pixel 4 XL has exposed what this tiny chip actually looks like, in addition to revealing other details about its innards.

Like most modern smartphones, the rear glass panel of the Google Pixel 4 XL has been glued to the chassis with the help of strong adhesive which requires a lot of heat to pry open. New for 2019, the wireless charging coil & NFC that are stuck to the glass back, use spring contacts which makes the device a tad more repair friendly than last year.

The teardown revealed that removing the battery was fairly simple accrediting to elastic pull tabs and some IPA (Iso-Propyl Alcohol). However, below the battery is the thin flex cable for the Active Edge feature which can easily be torn if the handler is not careful.

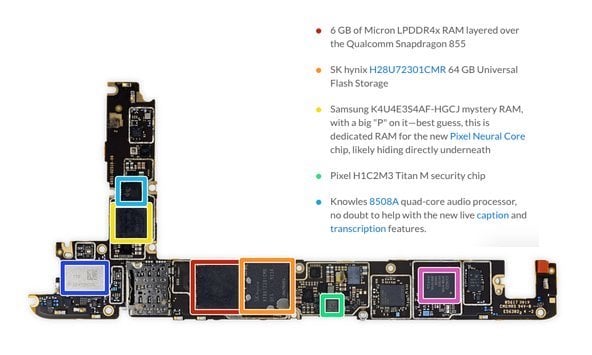

Next in the line, was the slender motherboard which is held in place via T3 Torx screws and several brackets that were carefully removed. As the images show, the 6 GB of Micron LPDDR4x RAM is placed next to the Qualcomm Snapdragon 855. On the same side of the board is Titan M security chip, Knowles 8508A quad-core audio processor, and dedicated RAM for the Pixel Neural Core chip.

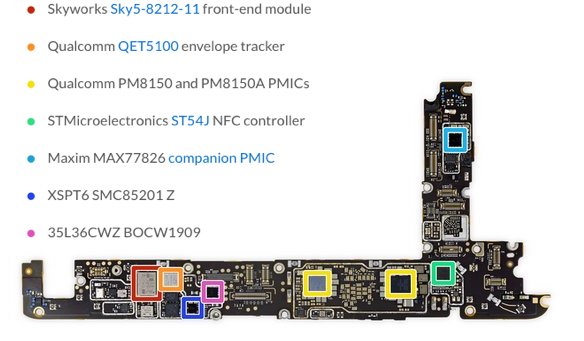

The other side of the motherboard houses other essential components like the Sky5-8212-11 front-end module, Qualcomm QET5100 envelope tracker, STMicroelectronics ST54J NFC controller and Maxim MAX77826 companion PMIC.

The motherboard extraction was followed by removal of a unified chunky component that features the earpiece speaker, mic, ambient light sensor, and the Soli chip which was previously mentioned.

All seemed fine until the next step which was dis-assembly of 90 Hz display. Like the rear panel, the display assembly has been stuck to the chassis, however, the adhesive is much stronger, therefore it is highly unlikely to take the screen apart in a single piece. Nevertheless, display panels are usually taken apart only during the replacement process in case they have broken already.

Editor’s Pick: Samsung has announced 12GB RAM and UFS 3.0 storage combo for mid-range devices

Interestingly enough, the display panel of the Google Pixel 4 XL is manufactured by none other than Samsung who also supplies panels to OnePlus but has not yet treated its own smartphone with a high refresh-rate display.

To wrap things up, iFixit experts have appreciated the use of standard T3 Torx screws across the device and east pull tabs for the battery. However, this is where the good bits end, all repairs require access through the back panel which is not the easiest to remove. Moreover, as previously mentioned, display replacement requires complete disassembly of the phone. All factors inclusive, iFixit has given the Pixel 4 XL a repairability score of just 4 out of 10.

(source)

UP NEXT: Vivo NEX 3 5G smartphone lands in Taiwan just as 5G rolls out in the country