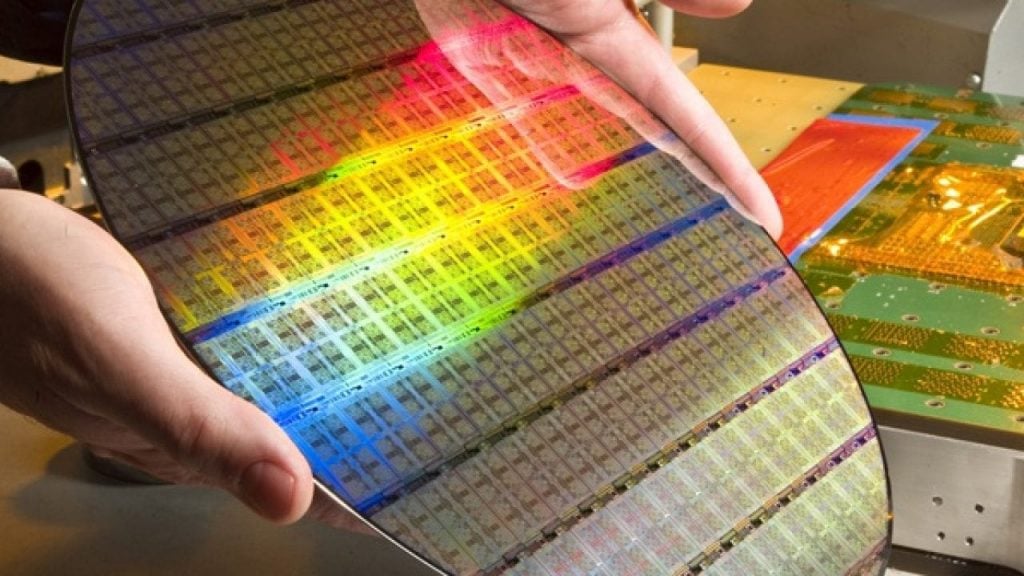

The 3 nm era has officially started in chip production. Manufacturers such as Samsung and TSMC have started the production process for chips that develop with this technology. It looks like TSMC will start shipping 3nm chips to Apple for the iPhone 15 series. Although this situation is good in terms of performance and energy efficiency, its reflection on costs has already begun. TSMC’s wafer prices double from 7nm production to 3nm.

TSMC’s wafer prices double from 7nm production to 3nm

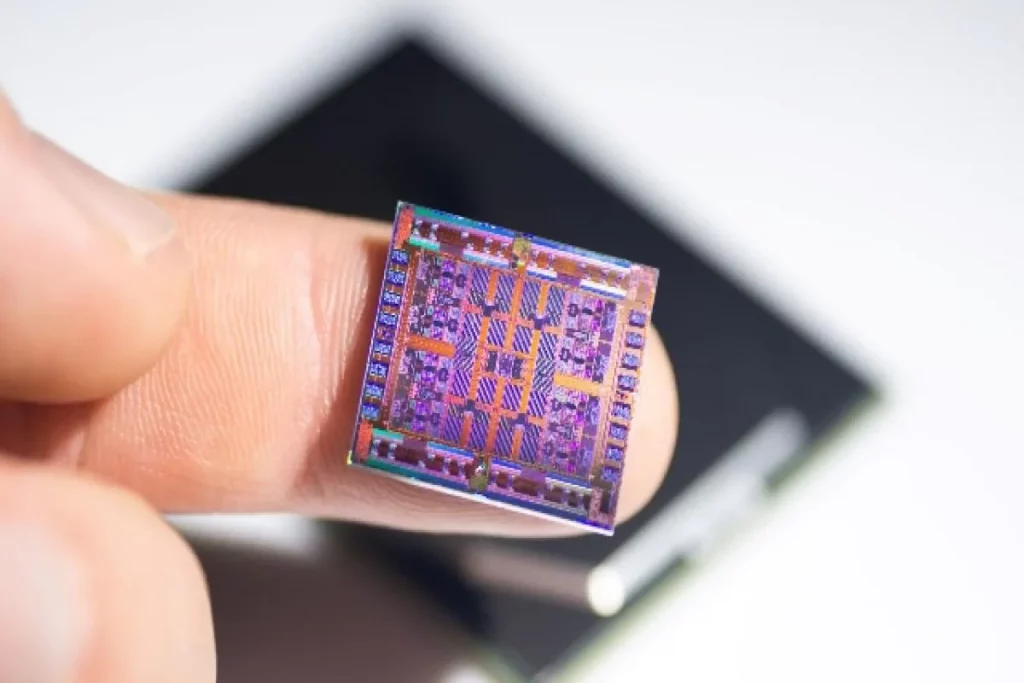

The A17 Bionic chip developed by Apple for the iPhone 15 series will be produced by TSMC, the world’s leading chip foundry, using a state-of-the-art process node. Simply put, the lower the process node number, the smaller the transistors used in a chip allowing more transistors inside a chip, the more powerful and energy-efficient it is. This process causes more advanced processors to emerge every year.

For Example, iPhone 11 had 7nm A13 Bionic SoC, released in 2019 that carried 8.5 billion transistors in each chip but iPhone 14 Pro and iPhone 14 Pro Max had the A16 Bionic chipset under their hoods. Unfortunately, maintaining the progress we’ve seen in the past is getting harder and harder each year.

Both TSMC and Samsung have plans for 2nm chips starting in 2025 and it is even possible that we will see 1nm by 2030. Although these developments have many advantages, they also come with costs. According to the latest reports TSMC plans on charging more than $20,000 for 3nm wafers. When the foundry moved from 7nm to 5nm, wafer pricing rose 60% from $10,000/wafer to $16,000/wafer.

At first glance, these costs do not make sense for the end user, but the increase in prices is inevitable. Based on this, it is possible to say that the iPhone 15 and other flagship models will come out at a higher price than expected. Especially considering that the cost increase is not limited to wafers.

RELATED:

- Apple’s A17 chip will be fabbed on TSMC’s next-gen 3-nm node: Report

- Flagship Snapdragon 8 Gen 2 and Dimensity 9100 SoCs Manufactured by TSMC, Alongside Snapdragon…

- Apple will be TSMC’s first 3nm chip customer, but not for the iPhone 14

- TSMC to exclusively manufacture next-gen Qualcomm Snapdragon flagship chips

- TSMC’s 3nm chips to launch in early 2023, 2nm Technology is also On the…