ViVo X3 is the one of Chinese smartphone that alre3ady release few days ago, this is the world’s thinnest Android smartphone since only has 5,75mm body thickness, and now we want to show you the teardown of this phone.

the new Vivo X3 has more highlights, such as high-end DAC chip ES9018, L-type single-sided layout design, customized main components. A distinctive feature of the models have always caught my destruction desire, so thin! Which actually has a kind of design, components, what is different? I believe you must be very curious, well it would meet at our curiosity. Note: The dismantling vivo X3 models for the mobile version, support for TD-SCDMA + GSM dual SIM functionality.

From X1, X1s, Xplay to the current X3, you can find them a common characteristic, that is the three-body back shape, so I want to disassemble or start with the upper and lower ends of the plastic cover to start, do not think, certainly underneath the lid screws with metal back cover, back cover snaps upwards can be removed.

Really right, we see a very familiar design style, in general, in the super-slim design to do this is very reasonable, but also more convenient for some “cheap hand,” the user’s own demolition of the play. Directly across the body with a thin plastic cover a little crowbar can be opened.

Two covers need to be removed after opening the 12 cross visible screws.

In the next steps required before the first slot out, vivo X3 mobile version supports TD-SCDMA + GSM dual SIM functionality, a slot can drag two SIM cards, the Micro SIM + Nano SIM combinations.

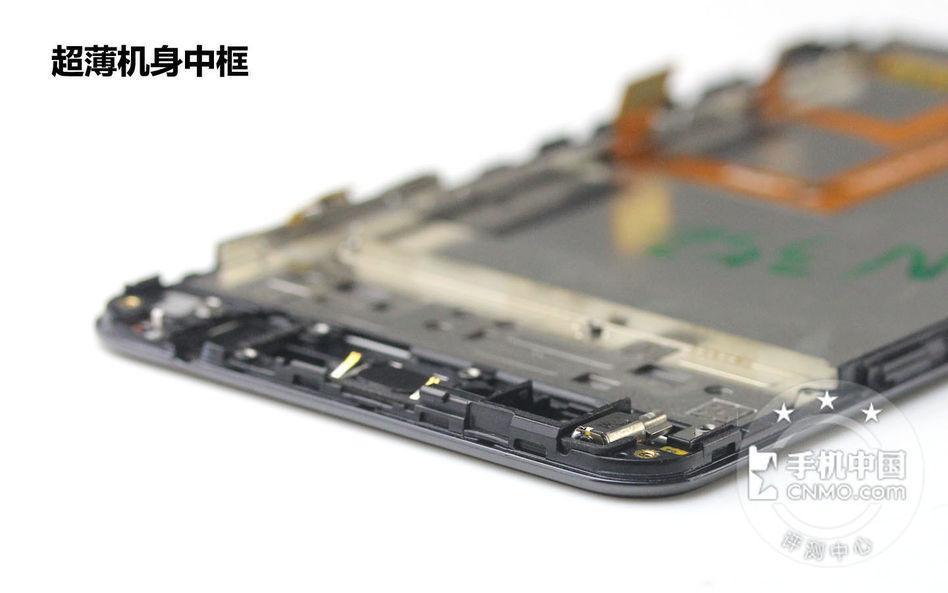

Body frame is made of metal back cover with buckle fixed in the form of the metal cover removed by pushing upward.

The overall strength of the metal cover is very high, breaking his hand, then basically breaking does not move.

Metal back cover with integrated volume, power switch button, and there are pads to fix, but also can play a role in shock absorption.

After removing all the screws to be, then you can remove the speaker, camera cover two parts of the.

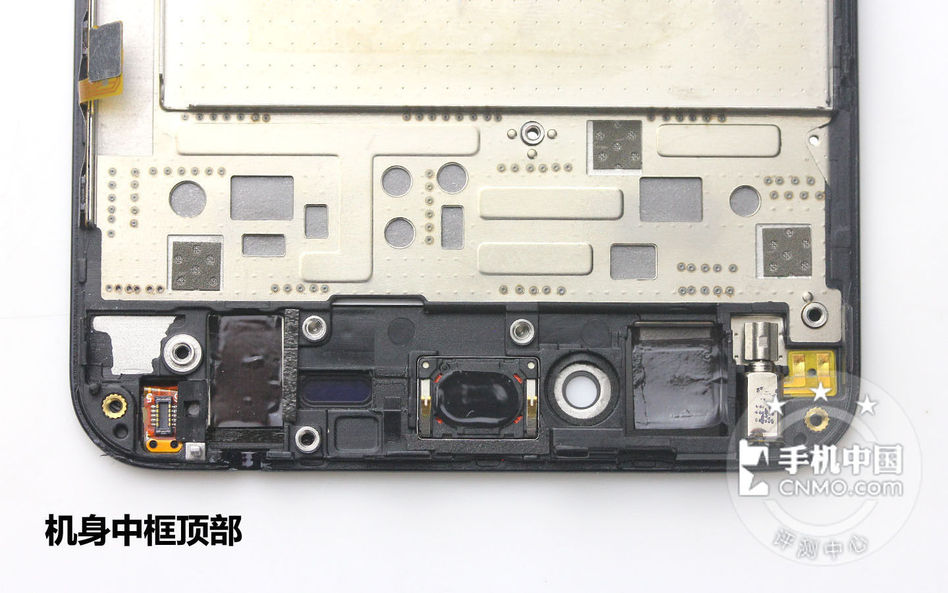

Integrated semi-open sound chamber closeup.

In the sound chamber and the cover plate on the printed circuit, connected to an antenna with the body, the plastic cover but also to ensure the strength of the signal.

Let’s look at the camera part of the cover, it is generally part of a metal material, both sides of the plastic. The partially integrated with the camera lens cover and flash hood.

Camera head cover plate back.

Batteries can be seen after the removal of a large thermal paste paper , basically covering to cover the place, disassemble process sticker basically abolished.

The next part of the motherboard , battery, etc. will be displayed in the front part.

Battery removal more difficult, the body of the first disconnect all cables, and then need to use a long thin fins along the bottom of the stick from the battery to the left of the double-sided adhesive tilt, can not use brute force, the battery is thin.

vivo X3 is equipped with a 2000 mAh battery, while the battery is thin, but the overall hardness is very high, the entire demolition process battery basically no deformation.

Take a look at the thickness of the battery, about 2.97mm or so.

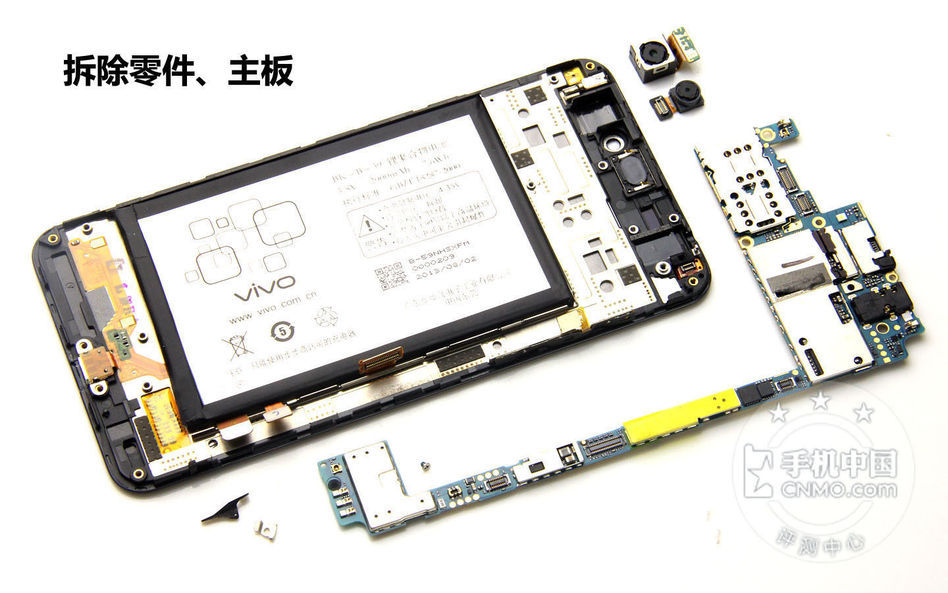

Disconnect the cable, remove the two camera, there is a screw on the motherboard, then L-board can be very smoothly remove it.

Pre-megapixel wide-angle lens.

800-megapixel main camera.

Motherboard screws, SIM card slot shrapnel. Statistics, a total of 15 fuselage cross screw removable.

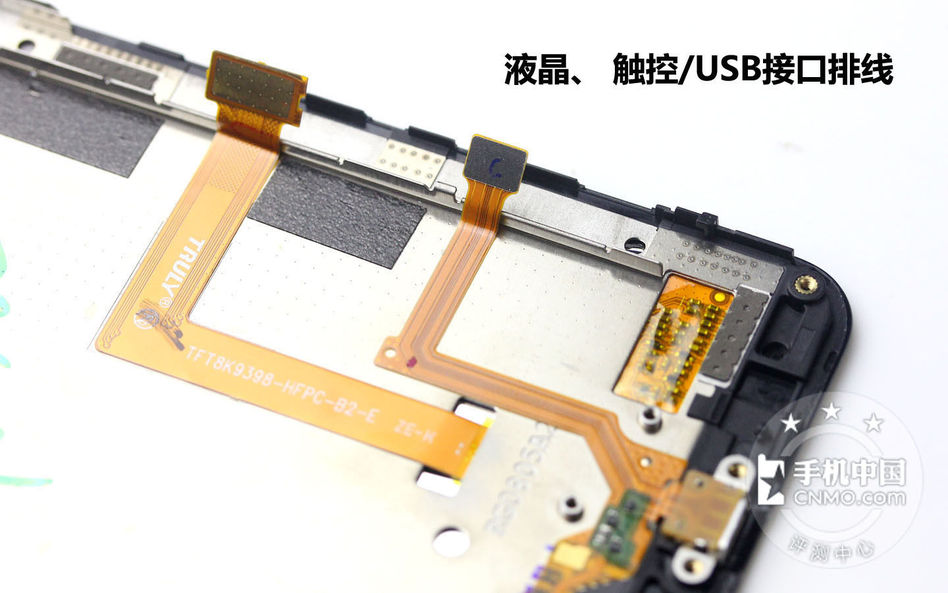

Box portion of the fuselage relatively high degree of integration, including the screen, touch cable, USB, vibration unit, handset, etc. These basic components can not be removed.

In the box at the top close-up.

Vibration unit close-up.

Handset, headset interface features.

Cable part of the close button.

LCD screen, touch, and a USB cable.

USB interface features.

We split-off compared to the previous models, vivo X3 entire screen frame part is very thin, coupled with ultra-thin batteries, motherboards and other components, the achievements of 5.75mm thin body.

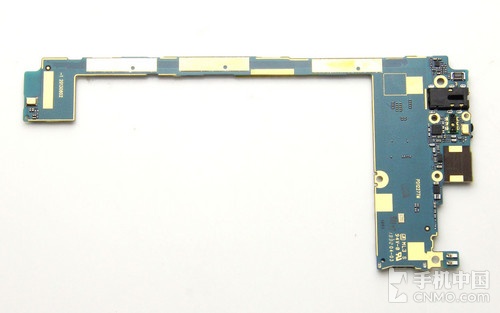

Let’s look at some more features of the motherboard, vivo X3t using the L-shaped single-sided layout design, that is part of the whole chip is designed in the side of the motherboard, reducing the thickness of the motherboard.

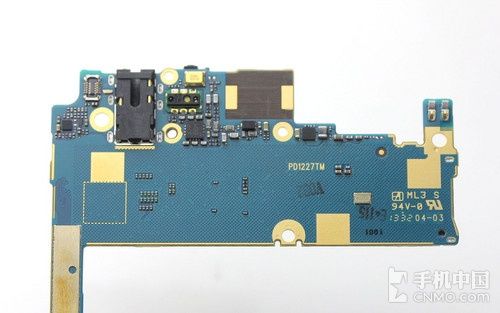

Back of the motherboard is almost no comparison of total chip area, there are only a few very small IC chip and the light sensor.

Motherboard positive feature, the vast majority of the surface of the chip and integrated cable interfaces.

Back of the motherboard just some small footprint of the IC chip, no larger area of the chip, eliminating a lot of space.

Bottom of the motherboard speaker closeup.

INVENSENSE (should Legg Mason) MPU 3050: three-axis gyroscope.

Unfortunately, due vivo X3t chip parts are protected with a shield and shield directly soldered on the motherboard, I can no longer be removed temporarily, due to subsequent evaluation of the needs, we want to preserve the this phone. But it does not matter, we will have a chance after the violent dismantling of the article, to the time together to see if it is known as single purchase price of 300 + DAC chip ESS9018.

Summary: From the point of view the overall workmanship, vivo X3 is still good, and it is customized components, L-sided layout design, high-strength body frame, one semi-open sound chamber features, both for its slim contributed fuselage, while 5.75mm fuselage into the top of the DAC chip ES9018, but also make it level again in the mainstream breakthrough on the road to become vivo differentiation for another new. Then again, looking at the phone itself disassemble workmanship is of quality considerations aside performance, experience and so they see the wisdom of benevolence see SAGE factors, we can say vivo X3 is still very worthy of recognition, especially is an innovative single-sided fabric panels and custom parts impressed me was very profound.